Upgrading Vintage Tower Speakers Part 1: Refinishing

I go thrift shopping for electronics quite often. Where I am, finding any good electronics will be a challenge. But when you hit it big, it's REALLY big. An example are these Realistic Optimus T-200's which were only 15 dollars! I had no idea if they worked at all outside of the condition of the speakers, but at that price I'd still be getting some really cool cabinets for cheap. I'll delve into the electronics in a future post, as we are going to sort out their condition first.

Once I finished the upholstery, I noticed the jersey material starting to tear at certain staples. This is quite worrisome, but I don't want to pointlessly apply super glue or some quick patch-job to it and ruin the particle board frame. I'll be periodically looking at these to make sure they aren't advancing at all, but I suspect the friction of the frame and fabric will be enough to keep them from getting worse. As for the emblem, I gently pushed it back into place through the fabric, and so far it's holding position with just the friction of the rivet stems and plywood. Since this is working, I won't be bothering with it.

Here's the final result of the reupholstering! It turned out a bit better than I expected if I'm honest, but being able to see the frame through the jersey material is a bit disappointing. Outside of that and the fabric tearing I think it looks quite nice compared to before! With that sorted out, let's work on the worn out veneer.

They do have a bit of wear and tear from wherever they were before. The veneer is worn the most on top, where possibly a plant pot sat and etched a ring into the surface. The sides are also a bit faded but still not bad. The acoustic fabric is quite nasty though, being off-brown stained and lint-speckled. My goal with this is to make the cabinets look snazzier and sleek. I will be using these in my room as home theater speakers, so I would prefer they didn't stick out like a sore thumb. We'll start with the grille as that's what I'm hoping will be the simplest. This will technically be my first reupholstering project, so hopefully it goes well!

The frame itself is made of particle board, which is less than ideal in terms of strength, but might work to my advantage. When turned over, you can see the many staples that hold the fabric onto the frame. My game plan was to first go over them with a flat head and pry one side up, then go back over them with plyers to pull them out. This worked quite easily as the particle board was weak enough that the staples popped right out. Once that was done, it came time to remove the badging, which was surprisingly riveted into place. With some prying at with a pair of needle nose plyers, I less than gracefully got the back side loose and was able to remove the badging. Now it's time to buy some new fabric.

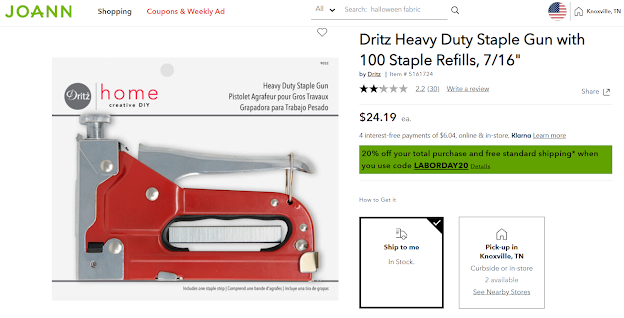

After measuring the old fabric, I looked to Joann to get some acoustic fabric to replace it. To my surprise, they not only sold it online but in store as well! Or so I thought. When I visited the store in person, there actually wasn't any for sale and the associates had never actually heard of it ever being sold there. *sigh* Oh well, I decided that a jersey material would likely be thin enough for this and though it might have some interference, I couldn't immediately tell with my highly advanced Move-It-Next-To-Your-Ear-While-Music-Plays test. While I was at Joann's I got myself a most definitely overpriced upholstery staple gun. I was pretty sure it wouldn't do any better than my readily available wood staple gun, but thought that I should try the "proper way" first. As suspected though, the cheap stapler kept either jamming or bending itself. The wood stapler did much better and did no damage.

Once I finished the upholstery, I noticed the jersey material starting to tear at certain staples. This is quite worrisome, but I don't want to pointlessly apply super glue or some quick patch-job to it and ruin the particle board frame. I'll be periodically looking at these to make sure they aren't advancing at all, but I suspect the friction of the frame and fabric will be enough to keep them from getting worse. As for the emblem, I gently pushed it back into place through the fabric, and so far it's holding position with just the friction of the rivet stems and plywood. Since this is working, I won't be bothering with it.

Here's the final result of the reupholstering! It turned out a bit better than I expected if I'm honest, but being able to see the frame through the jersey material is a bit disappointing. Outside of that and the fabric tearing I think it looks quite nice compared to before! With that sorted out, let's work on the worn out veneer.

I really love the look of veneer, especially on speaker cabinets. Newer speakers are always some kind of plastic or weird looking textured wrap, so having some nice veneer cabinets is a blessing for this reason alone. It is quite unfortunate that it's in such bad condition, but I figured this would be a good a time as ever to give it a new start. I'll be foregoing the tabby cat orange stain that it currently has, and will be going a darker walnut-like color. I know nothing of staining either, so I'm hoping that after my rudimentary research and YouTube tutorial session I'll have gained a skill. When looking for a good stain to apply, I came across one called "Kona" by Varathane, which was the closest I could find without going overboard. First I inadvertently got a Stain+Poly combo without knowing what Poly even was. Apparently Polyurethane is a sealant and sort of clear coat that protects the final product from moisture and other things. This is Definitely important, but as I found out this drastically changes the process. I sanded down all 3 sides to remove the current stain and give it a smooth finish. I then applied the Stain+Poly and let it sit for a minute. When I tried removing it, clumps quickly started forming. I thought this was something I did wrong (technically true), but apparently that's due to the poly. I went back and got stain and poly in separate stages and tried again, this time with much better results.

I absolutely love how the stain came out! It looks so amazing in this shade! I was really afraid that I'd be losing absolutely all the color the veneer originally had when I started using the stain, but it ended up being a beautiful orange-brown mix! I couldn't be happier with the results and feel that this was the crowning achievement for this project. I still need to apply the poly, but I'll be doing that on my next day off since this whole process of prepping and staining took quite a bit of time and requires good weather all day. All in all I'd say that this was a success so far! Now to work on the electronics, which should be even more fun!

Comments

Post a Comment